Table of Contents

What is the IEC 61482 standard?

In this standard, protective fabrics that protect against fire go through some testing to determine their quality. These tests are mostly thermal and electrical as the fabric may have to work in similar circumstances. Short circuit and fire outages are common hazards that can occur in any workplace or home.

Multiple tests ensure that these fabrics will not fail at the time they are most in need. When this fire retardant fabric goes through these tests, its limits are easy to see and this helps us to determine whether the fabric is eligible for fire and electric protection. If these standards don’t exist then there would be no check and balance as people will cut corners to get cheap fabrics that are not safe to use. In short words, these fabrics save lives and without the IEC 61482 Certificate, it can be hard to determine between good and bad fabrics.

Requirements for the standard

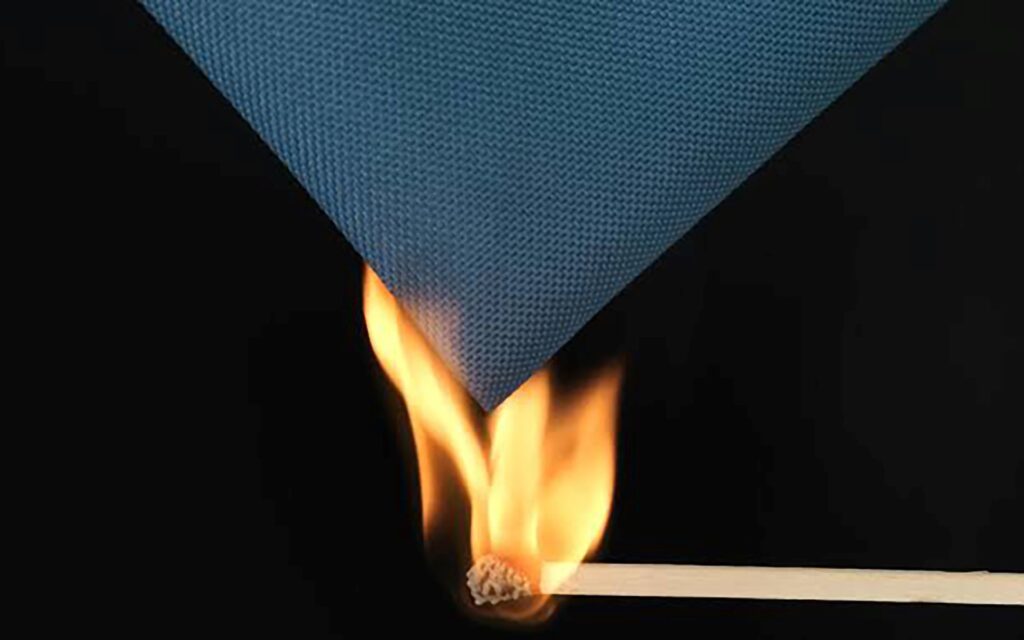

Fabric testing is done under flames. The direct contact to the fabric reveals all the flaws in the fabric. In addition, the fabric must protect the wearer’s skin. Buttons, zippers, and other similar components on the fabric should not cause any harm to the body when heated. Furthermore, if the zippers and buttons add to the danger, they should be made from materials that work better in fire and electrical conditions. The Flame Retardant fabric should not melt under heat and electrical exposure. Clothing made from these fabrics should cover most exposed skin to prevent any burns. Two-part wear involves an overlay of at least 20 cm between the jacket and the pants during all operations. Materials in clothing can only be fire retardants. The substance does not ignite or shrink and should not reach a 5% shrinkage level at any time in the testing phase in IEC 61482.

Arc Test

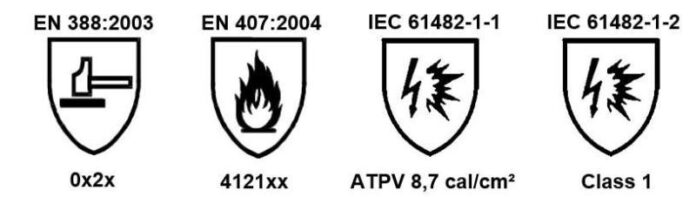

Part 1-1, Test Method 1: The arc rating of flame retardant material or clothing (ATPV or EBT50) shall be known by these tests. Both ATPV and EBT are found out in the same open-arc test. The first result is the arc rate of cal/cm2 is take into note. If the material has a higher thermal insulation value than the arc strength, the material is of high quality according to the EN IEC 61482. If not, the fabric continues to burn as the fabric is now known to be less effective. Rejecting the lowest quality fabrics ensure are safer and hazard-free environment. The higher the quality and strength of the fabric the more protection it provides.

Usually, the EBT consists of knitting the wearer’s clothing and making it less prone to burning, without being tough to wear. You can never determine which protective Flame Retardant fabric is best on the basis of the ATPV or EBT quality ranking. They’re known for more functionality reasons. The energy breakopen threshold (EBT) is the incident energy in a substance that opens up 50 percent of it. The open area of at least 1.6 cm2 is determined by the open split. The higher the value, the higher the defense value.

Appropriate heat transfer is important in IEC 61482. Defense of the fabric is dependent on the efficiency of heat transfer of the fabric. Tests on an individual or multiple layers of the substance may be performed on both ATPV and EBT. When you test different layers, you get a better value than when you test the content individually. This is due to the air trapped in the material’s insulation and safety effects.

Further information about IEC 61482 Certificate

This form of the standard is common in the United States of America. In this standard process, the ATPV or EBT50 is found through testing. The value of the ATPV is the value that ensures the safety of 50% in the second combustion process. More benefits, more security is the result this Fire Retardant fabric standard hopes to achieve. In America, a minimum ATPV value of 8 is required for worker wear fabrics to electrical arc risks.

Buying and using fabrics that do not fall under such standards can be against the law. Furthermore, it is not only against the law but is also ethically wrong to put people’s lives in danger just to save a few bucks. It is better to spend a few extra bucks on IEC 61482 Certificate fabrics rather than carry a lawsuit and put lives at stake.

The goal is not to determine the energy content, but rather to analyze the fabric after being under electrical arc for defects in the seams, fasteners, and all other accessories. For the specifications of the welding model, the requirements set out in this specification can apply. After getting this IEC 61482 certificate the fabrics are safe to wear and will perform well under emergency circumstances.